An ultra-thin, ultra-flexible electronic material that could be printed and rolled out like newspaper for the touchscreens of the future has been developed by RMIT University researchers. The touch-responsive technology is claimed to be 100 times thinner than existing touchscreen materials and so pliable it can be rolled up like a tube.

To create the new conductive sheet, researchers used a thin film common in mobile phone touchscreens and shrunk it from 3D to 2D, using liquid metal chemistry. The nano-thin sheets are readily compatible with existing electronic technologies and because of their incredible flexibility, could potentially be manufactured through roll-to-roll (R2R) processing just like a newspaper.

Lead researcher Dr Torben Daeneke said this pioneering approach cracks a challenge that was considered unsolvable.

“Most mobile phone touchscreens are made of a transparent material, indium-tin oxide that is very conductive but also very brittle. We’ve taken an old material and transformed it from the inside to create a new version that’s supremely thin and flexible,” he said. “You can bend it, twist it, and it could be made far more cheaply and efficiently than the slow and expensive way we currently manufacture touchscreens.

“Turning it two-dimensional also makes it more transparent, so it lets through more light. This means a mobile phone with a touchscreen made of our material would use less power, extending the battery life by roughly 10%.” The material could also be used in other optoelectronic applications, such as LEDs and touch displays, and possibly in future solar cells and smart windows.

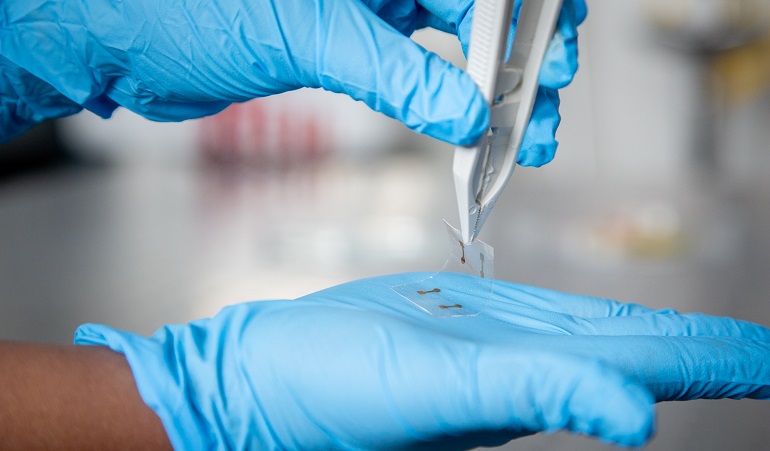

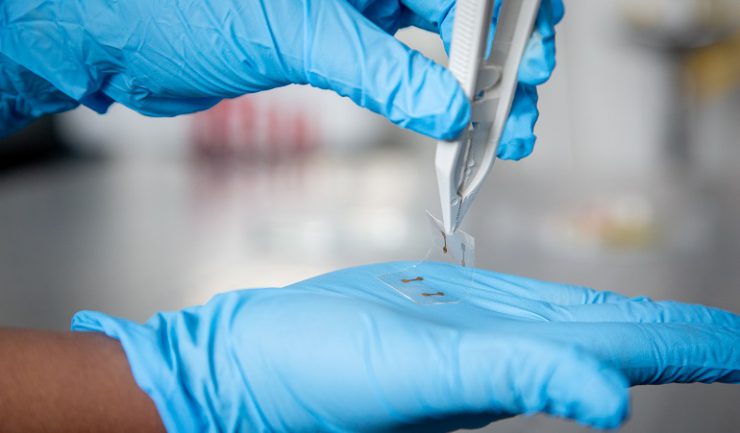

The research team have used the new material to create a working touchscreen, as a proof-of-concept, and applied for a patent for the technology.

The research, with collaborators from UNSW, Monash University and the ARC Centre of Excellence in Future Low-Energy Electronics Technologies (FLEET), was published in the journal Nature Electronics.