In 1993 Paul Keating won the ‘unwinnable election’, Shane Warne bowled the ‘ball of the century’ and Dyson launched its first vacuum cleaner, the DC01, which would become the best-selling vacuum cleaner in the UK. It was the world’s first cyclonic vacuum cleaner and the end result of 5,127 prototypes.

21 years later and Dyson has notched up 4,000 patent applications for more than 500 inventions and its engineers are working with over twenty of Britain’s universities to develop a pipeline of technology 25 years long.

Dyson prototypes are guarded with James Bond (or perhaps Sir James) levels of secrecy; they are never referred to by name but given a secret project code and are protected by biometric security at Dyson’s research and development headquarters in Malmesbury, Wiltshire.

The company has turned out some innovative products including bladeless fans and super-efficient hand dryers, but not all the ideas got off the ground. On Dyson’s 21st birthday it shared three prototypes that never made it out of the lab, including one that looks very much like a precursor to Google Glass.

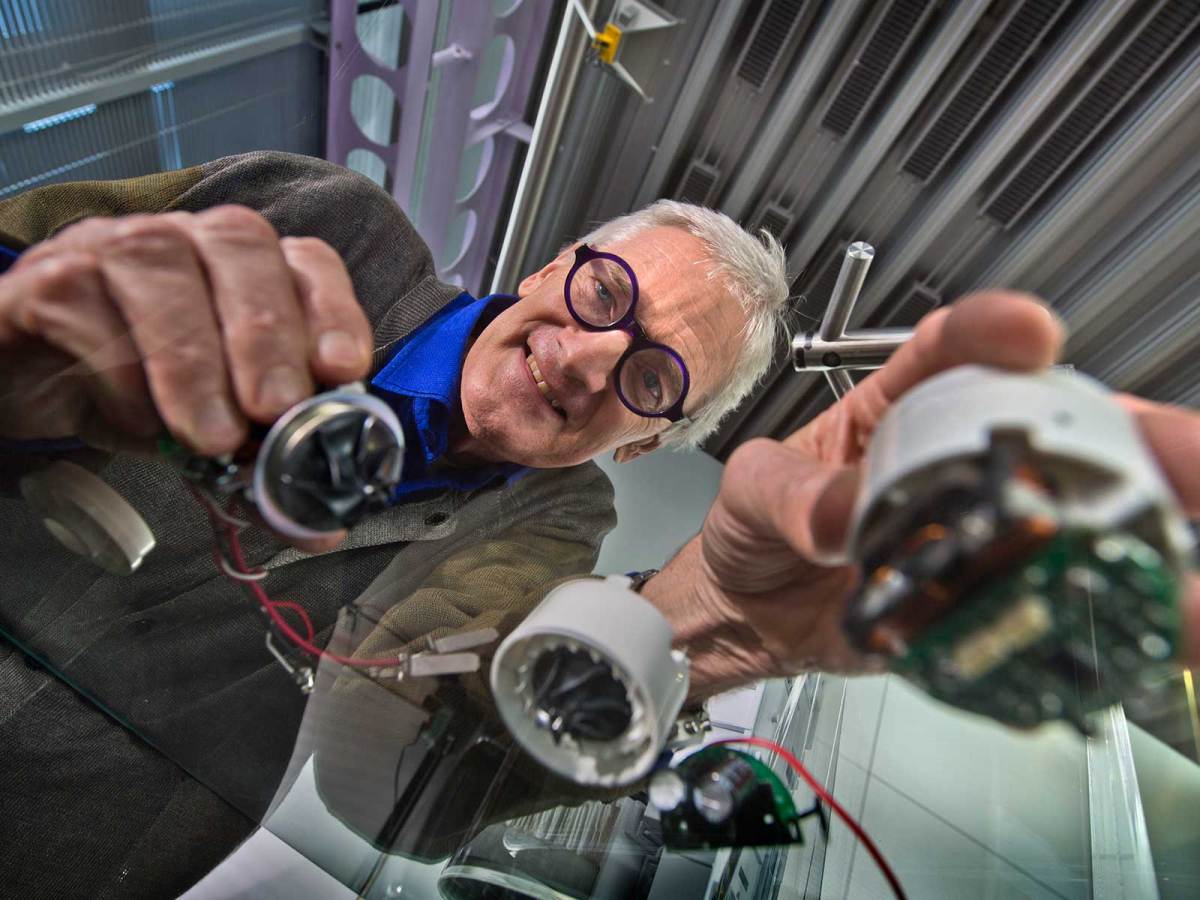

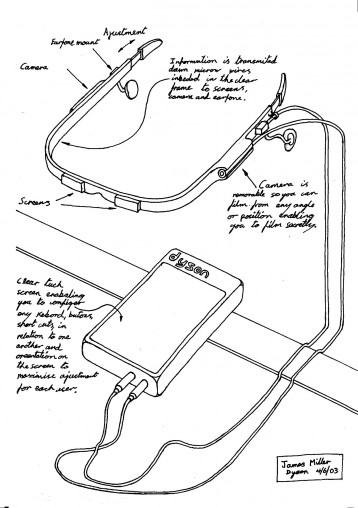

Dyson Halo (N066), 2001

Dyson describes this project as “an augmented reality headset featuring full colour 3D, heads-up display. It was a portable, head-mounted, wearable computer, that could be carried in the user’s pocket, but which worked as a communications device and PC. It had a headset that could be worn on your head like a pair of glasses and used audio prompts and visual cues to overlay information on your surroundings.”

Sound familiar?

“In the prototype, the user could see and use several different key applications. A virtual personal assistant, similar to Siri, could read out emails and interpret basic voice commands,” Dyson said.

The headset could be detached from the wearable computer, and the mobile device could be docked into a monitor to become a desktop computer, giving the same effect as plugging a laptop into a TV. It also featured a control device worn of the wrist that allowed the user to move the virtual cursor across the display.

The project was started in 2001, but was put on hold after three years of research and development so Dyson engineers could focus on expanding their technology in the USA. But Dyson says that elements of the technology are now being used in future research projects. A voice controlled vacuum cleaner perhaps?

Click here to sign up for our free daily newsletter

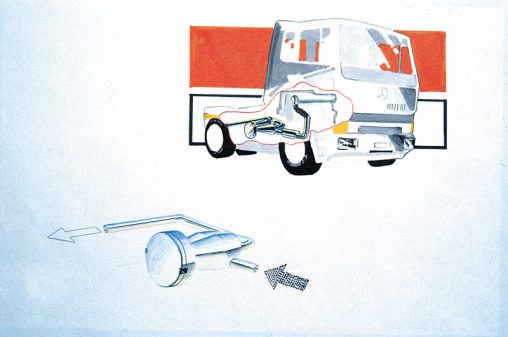

Diesel Trap (X007), 1997

In 1997 Dyson engineers undertook the challenge of reducing air pollution caused by diesel engines by adapting the technology used on their vacuums to filter air.

“Fine diesel particles are around 2.5 microns in size. The cyclones on Dyson vacuum cleaners can filter particles down to 0.5 microns, ensuring homes remain clean. In 1997, Dyson engineers began investigating whether this technology could be applied to diesel engines – to clean the air.”

Here’s what Dyson said on the project:

Initial prototypes focused on cyclones but the required energy consumption was too high. Condensing oil onto the small particles to increase their radius came next. But the particle size was inconsistent, allowing inaccurate results, so the focus turned to the use of electrostatics and the final system used an electrical discharge to ionise and collect these particles which were then burned off in an oxygen rich environment.

At the time, Dyson had no plans to make a car. All too similar to James Dyson’s battle with the vacuum cleaner bag market, manufacturers were not interested in the technology instead turning to ceramic filters. Diesel engines now use particulate filters which clog, and as a result drop in performance – the clogging particles are regularly burned off to improve efficiency.

- Dyson Diesel trap

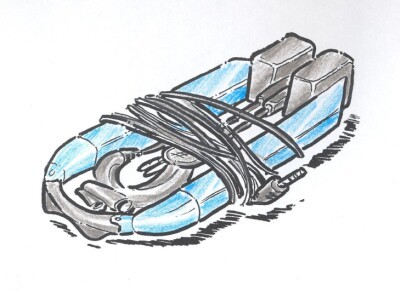

The Dyson Fuel Cell

Hydrogen fuel cells convert chemical energy from hydrogen and oxygen into electrical energy. Fuel cells require a large, constant source of both hydrogen and oxygen to run, but produce electricity continuously as long as these elements are supplied.

For three years, 10 Dyson engineers worked to adapt a Dyson digital motor so it could sit at the heart of a fuel cell. The aim was to increase performance whilst reducing size. The results were impressive. The compact, lightweight and highly efficient digital motor V4HF resulted in a 20 per cent increase in power density and improved efficiency. The start-up time became almost 3 times faster.

Dyson prides itself on lean engineering. Now that the potential has been proven, Dyson engineers are exploring other possibilities for the Dyson digital motor.